Views: 3 Author: XD laser Publish Time: 2021-03-25 Origin: XD laser

Industrial fiber laser welding equipment is also called handheld fiber laser welding machine. In the realm of modern manufacturing, precision and efficiency are paramount. Fiber laser welding equipment has emerged as a leading technology for various industrial applications, offering unparalleled precision and speed. This blog post will delve into the versatility of industrial fiber laser welding equipment and explore the types of materials it can effectively weld.

Fiber laser welding is a process that utilizes the intense light emitted by a fiber laser to join materials together. The laser beam, which is highly focused and controllable, melts the materials at the joint, creating a strong bond without the need for filler materials. This process is characterized by deep penetration, minimal heat-affected zones, and excellent precision, making it suitable for a wide range of applications.

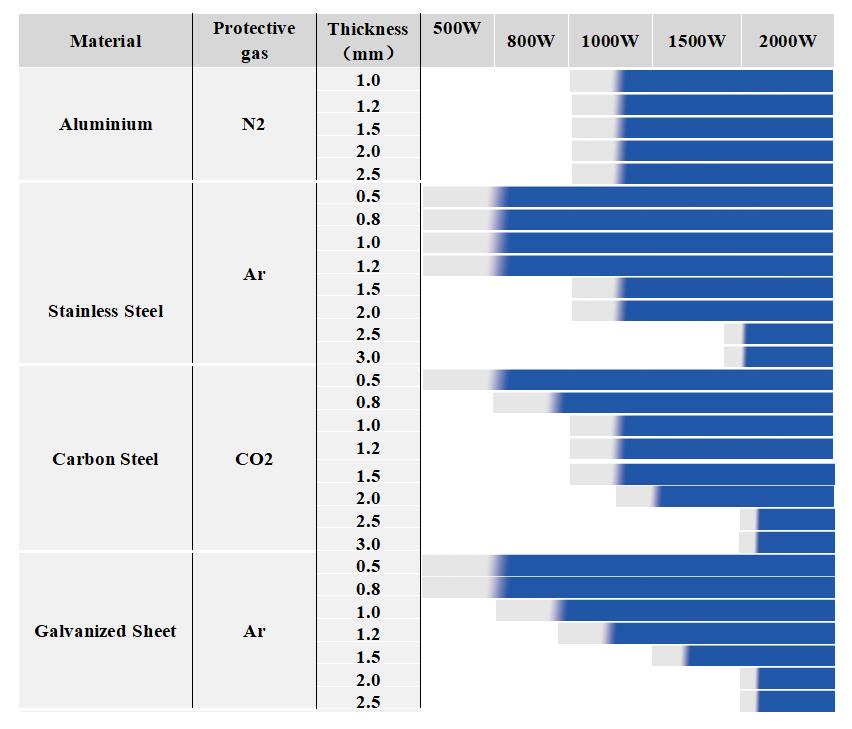

Fiber lasers are particularly adept at welding metals due to their high power density and precision. Here are some common metals that can be welded using fiber laser technology:

Stainless Steel: Known for its corrosion resistance, stainless steel is frequently welded using fiber lasers for applications in the automotive, aerospace, and medical industries.

Aluminum and Aluminum Alloys: Fiber lasers can efficiently weld aluminum, which is beneficial for lightweight components in the automotive and aerospace sectors.

Copper and Copper Alloys: Copper's high thermal conductivity makes it challenging to weld, but fiber lasers can achieve deep penetration with minimal distortion.

Titanium: This lightweight, strong metal is often used in aerospace and medical applications and can be welded with fiber lasers for high-strength bonds.

Steel: Carbon steel and low-alloy steels are commonly welded using fiber lasers for their structural applications.

One of the advantages of fiber laser welding is its ability to join dissimilar metals, which is not always possible with traditional welding methods. This capability opens up new design possibilities and cost savings in various industries.

Although less common, fiber lasers can also be used to weld certain types of plastics, particularly thermoplastics. This process is known as laser transmission welding and is used in the automotive industry for components like fuel tanks and in the medical field for device housings.

High Precision: The narrow and focused beam allows for precise control over the welding process, which is crucial for intricate parts.

Speed: Fiber lasers can weld quickly, reducing production time and increasing efficiency.

Minimal Distortion: Due to the localized heat input, there is less risk of warping or distortion.

Clean Process: Fiber laser welding is a clean process with no fumes or spatter, making it environmentally friendly.

Low Maintenance: Fiber lasers require minimal maintenance compared to other welding technologies.

Automotive Industry: For welding parts such as exhaust systems, fuel tanks, and structural components.

Aerospace: In the production of aircraft components where lightweight and high-strength materials are crucial.

Medical Devices: For the precise welding of surgical instruments and device housings.

Consumer Electronics: For assembling small and delicate components with high precision.

Jewelry Making: For intricate designs that require a high level of detail.

Fiber laser welding equipment is a versatile tool in the modern manufacturing toolkit. Its ability to weld a wide range of materials, including metals and certain plastics, makes it an invaluable asset in various industries. As technology continues to advance, the capabilities of fiber laser welding will undoubtedly expand, offering even more possibilities for precision manufacturing.

Whether you're in the market for a new welding solution or looking to improve your current process, fiber laser welding is worth considering for its efficiency, precision, and adaptability.

Welcome to contact XDLASER for details.