Views: 0 Author: XD laser Publish Time: 2021-04-13 Origin: XD laser

Are you still using plasma or other machine that has low precision and low speed?

Fiber laser machine for metal cutting is an equipment that use fiber laser to cut metal sheets and metal tube. We use fiber laser machine for many industries like advertising industry,sign making industry,sheet metal industry,kitchen ware industry,automobile industry.

Some small factories is going to change there plasma cutting machine to fiber laser machine in order to higher the work efficiency and get better cutting edge.

A fiber laser machine is a type of laser cutting system that uses fiber optic cables to deliver a high-powered laser beam to a cutting head. This advanced technology offers several advantages over traditional cutting methods, including:

High Precision: The laser beam can be focused to a very fine point, allowing for intricate designs and tight tolerances.

Speed: Fiber lasers can cut through metals quickly, reducing production times.

Versatility: Capable of cutting a wide range of metal types and thicknesses.

Low Operating Costs: Requires minimal maintenance and has low energy consumption compared to other cutting technologies.

1.Power

The laser power of fiber laser machine is always very high, from 1KW to 30KW. The laser power is getting higher and higher these days.

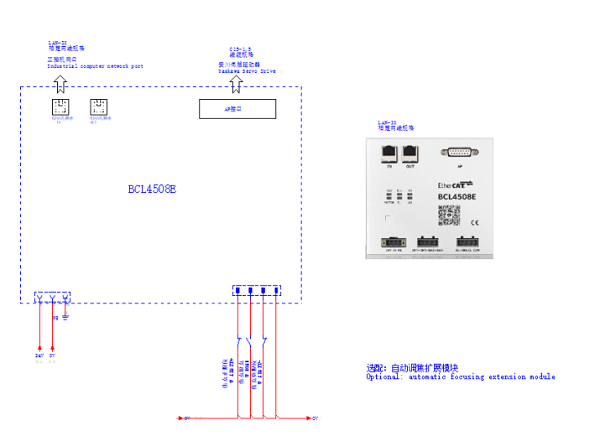

2.System

We need a CNC control system to operate the fiber laser machine. The most popular CNC control system for fiber laser machine is Cypcut. There are also Weihong,Au3tech and so on. Cypcut is the best for using. It uses G code and can support many other software.

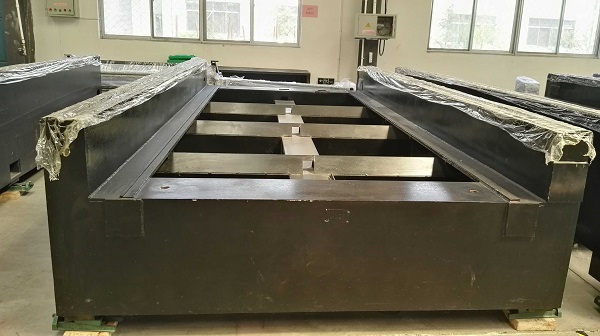

3.Body

Fiber laser needs stronger body in order to keep the stability during fast speed cutting. There are metal tube welding,metal plate welding and cast iron body. Steel welding body is the most suitable for fiber laser cutting machine.

The process of cutting metal with a fiber laser machine involves several steps:

Laser Generation: A laser resonator within the machine generates a laser beam. The beam is produced by pumping energy into a lasing medium, which, in the case of fiber lasers, is typically a special type of glass fiber.

Beam Delivery: The laser beam is transmitted through fiber optic cables to the cutting head. This allows for flexible positioning of the cutting head relative to the material.

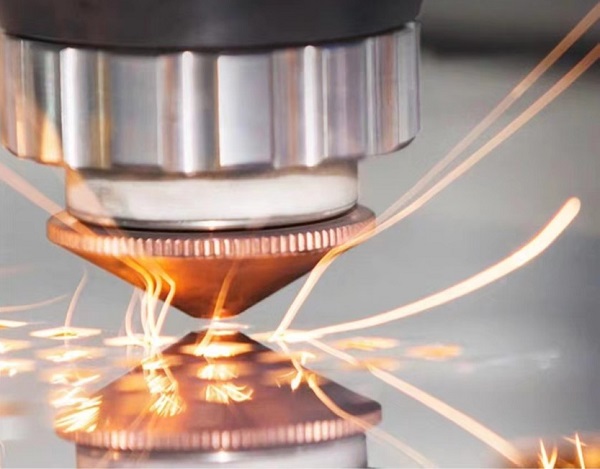

Focusing: At the cutting head, the beam is focused onto the surface of the metal using a series of lenses.

Cutting: The intense heat of the laser beam vaporizes the metal, creating a kerf (cut). An assist gas, often oxygen or nitrogen, is used to help with the cutting process by blowing away the molten material.

Control System: The entire process is controlled by a computer-aided design (CAD) system that translates the desired cut pattern into precise movements of the cutting head.

Fiber laser machines are used across a multitude of industries for a variety of applications, including:

Automotive: Cutting parts for vehicles, such as exhaust systems and chassis components.

Aerospace: Precision cutting of high-strength alloys used in aircraft and spacecraft.

Medical: Manufacturing of precision medical instruments and implants.

Construction: Cutting of metal components for building structures.

Electronics: Creating intricate parts for electronic devices.

Art and Design: Crafting detailed metal art pieces and designs.

The benefits of using a fiber laser machine for metal cutting are numerous:

Clean Edges: Produces smooth, burr-free edges that often require no further finishing.

Material Efficiency: Reduces material waste due to the precision of the cuts.

High Quality: Consistently high-quality cuts, even on reflective or hard-to-cut materials.

Operational Efficiency: Streamlines production processes and reduces downtime.

Environmentally Friendly: Produces less waste and noise compared to traditional cutting methods.

1.Clean edge high precision

When we cut the stainless steel sheet,carbon steel sheet,aluminum sheet,copper sheet and the pipe of the above material, we can get a very clean edge. By the way, the cutting speed is much faster than that of plasma cutting machine. The gap of the cutting line if extremely small, you almost can ignore it. Fiber laser machine can cut very small words. The precision can reach 0.03mm on precise fiber lasers.

2.Few consumable parts

The whole fiber laser machine almost do not have too much consumable part except the protect mirror,nozzle and so on. The price of protect mirror and nozzle are very cheap, around USD15. By the way, when send the machine, we send some nozzles for free. You can also buy some after finish them.

Generally speaking, fiber laser machine is the most suitable equipment for sheet metal cutting and metal pipe cutting.

The fiber laser machine for metal cutting is a testament to the power of modern technology in manufacturing. Its precision, speed, versatility, and efficiency make it an invaluable asset for a wide range of industries. As technology continues to advance, the capabilities of fiber laser machines will undoubtedly expand, offering even greater possibilities for innovation in metalworking.

In summary, if you're in the metalworking business, investing in a fiber laser machine is more than just a step up—it's a leap forward into a realm of cutting-edge manufacturing where precision and efficiency are not just goals, but the standard.

Welcome to contact XD laser for details.

Web: www.xdlasers.com

Whatsapp: +86-15169026664

Wechat/Skype: juliali01