Views: 0 Author: XDLASER Publish Time: 2024-05-09 Origin: XDLASER

In the realm of manufacturing and fabrication, precision and efficiency are paramount to achieving high-quality products and meeting customer demands. Among the diverse array of cutting technologies available, 300W CO2 laser cutting machines have emerged as a frontrunner, offering a compelling combination of power, precision, and versatility. These machines have revolutionized various industries, from crafting intricate electronics to shaping delicate designs in wood and acrylic.

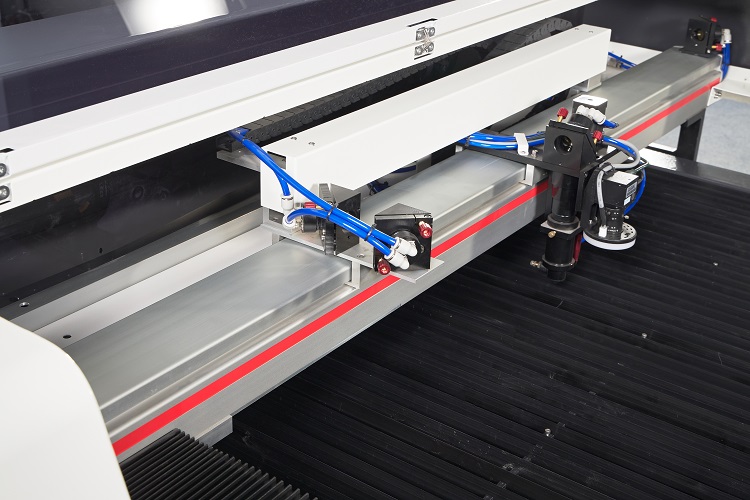

At the heart of a 300W CO2 laser cutting machine lies a sophisticated laser source that generates an intense beam of infrared light. This beam, precisely controlled by computer numerical control (CNC) software, is meticulously directed onto the material being cut, creating a focused heat source that vaporizes the material along its path. Unlike traditional cutting methods that rely on mechanical force or blades, laser cutting offers a non-contact process, eliminating tool wear and ensuring minimal material deformation.

The 300W power rating of these machines strikes a balance between cutting capability and affordability, making them suitable for a wide range of applications. This power level enables them to effectively cut through a variety of materials, including:

Acrylic: Laser cutters excel at cutting acrylic, producing clean, polished edges and intricate designs.

Wood: From delicate veneers to thick plywood, laser cutters can precisely cut a wide range of wood types.

Plastics: Various types of plastics, including ABS, PVC, and PET, can be effectively cut with a 300W CO2 laser.

Thin Metals: For applications requiring cutting of thin metal sheets, such as aluminum and stainless steel, a 300W CO2 laser cutter proves to be a valuable asset.

Leather: Laser cutting offers a precise and clean method for cutting leather, producing high-quality results for garments, accessories, and other applications.

Beyond its material versatility, a 300W CO2 laser cutting machine boasts several advantages that make it an attractive choice for businesses and hobbyists alike.

Precision Cutting: The focused nature of the laser beam enables exceptionally precise cuts, with minimal kerf widths and smooth edges. This level of precision is crucial for applications where intricate details and tight tolerances are required.

Non-Contact Process: The non-contact nature of laser cutting eliminates the need for physical tools, minimizing material deformation and wear on the cutting mechanism. This results in cleaner cuts, reduced waste, and lower maintenance costs.

Versatility: The ability to cut a wide range of materials, coupled with the precision and non-contact process, makes 300W CO2 laser cutting machines highly versatile tools suitable for diverse applications.

Speed and Efficiency: Laser cutters offer rapid cutting speeds, allowing for high throughput and efficient production. This is particularly beneficial for businesses that require consistent production of high-quality parts.

Safety: With proper safety precautions and training, laser cutting machines can be operated safely, minimizing the risk of accidents and injuries.

As technology continues to advance, 300W CO2 laser cutting machines are becoming increasingly sophisticated and affordable, making them accessible to a wider range of users. Their ability to deliver precise, high-quality cuts while maintaining efficiency and versatility has propelled them to the forefront of cutting technologies, transforming manufacturing processes and creative endeavors alike.

In conclusion, 300W CO2 laser cutting machines have established themselves as indispensable tools in the modern manufacturing landscape. Their combination of power, precision, versatility, and efficiency has revolutionized various industries, enabling the creation of intricate designs, high-quality products, and innovative prototypes with unparalleled precision. As technology continues to evolve, 300W CO2 laser cutters are poised to play an even more prominent role in shaping the future of manufacturing and fabrication.